Introduction and Current Market Scenario of the Boiler Water Treatment Chemicals Industry

Boiler water treatment chemicals play a critical role in maintaining the efficiency and longevity of industrial boilers by mitigating the adverse effects of impurities and scale formation. Boilers are integral to industries like power generation, chemical processing, food and beverage, and others where steam or heated water is required for various processes. However, the operational efficiency of these systems is often compromised by issues such as corrosion, scaling, and the accumulation of deposits. This is where boiler water treatment chemicals come into play, addressing these challenges and ensuring the optimal performance of boiler systems.

According to Cognitive Market Research the global market for boiler water treatment chemicals has been experiencing consistent growth due to the increasing demand for energy and the expansion of industries relying on steam generation. The rise of urbanization and industrialization, especially in developing economies, is further propelling the demand for efficient boiler systems and, consequently, the chemicals required for their maintenance. Additionally, stringent regulations surrounding industrial emissions and water quality management are driving the adoption of advanced treatment solutions, fostering innovation and development in the industry. The boiler water treatment chemicals market was estimated to be worth approximately USD 4526.5 million in 2024 and is projected to increase to USD 10134.5 million by 2032, with a compound annual growth rate (CAGR) of 10.60% during the forecast period, according to a recent market analysis Factors such as the growing emphasis on energy efficiency, cost reduction in industrial processes, and the increasing prevalence of environmental sustainability are contributing to this upward trajectory. The market is characterized by a mix of established players and emerging innovators, each striving to enhance the effectiveness, sustainability, and cost-efficiency of their chemical solutions.

What Are the Current Trends of the Boiler Water Treatment Chemicals Market?

Based on the research conducted by Cognitive Market Research the global boiler water treatment chemicals market is estimated to be worth approximately USD 4526.5million as of 2024. The boiler water treatment chemicals market is experiencing significant growth driven by key trends, including a rising focus on energy efficiency, sustainability, and customized solutions. As industries aim to optimize energy consumption and reduce operational costs, the demand for effective water treatment chemicals has increased, helping to improve heat transfer efficiency and minimize energy losses. Concurrently, the growing emphasis on environmental conservation has spurred the adoption of eco-friendly and biodegradable chemicals, with manufacturers developing solutions that balance performance with reduced environmental impact. The market is anticipated to expand at a compound annual growth rate (CAGR) of 10.60%, with a market value of approximately USD 10134.5 million by the conclusion of 2032. Additionally, the integration of real-time monitoring technologies is optimizing chemical usage, enhancing treatment effectiveness while minimizing waste.

The boiler water treatment chemicals market shows distinct regional growth patterns, with Asia-Pacific leading the market, holding approximately 45% of the global share. This dominance is driven by rapid industrialization, urbanization, and infrastructure development in countries like China, India, and Southeast Asian nations, alongside the growing demand for energy and the expansion of sectors such as manufacturing, power generation, and chemical processing. North America follows as the second-largest market, accounting for nearly 25% of the global share, due to its mature industrial base and stringent environmental regulations that promote the adoption of advanced water treatment chemicals to reduce emissions and optimize resource use. Europe holds a 20% market share, fueled by its well-established industrial base, strong sustainability focus, and the European Union's environmental policies that encourage the adoption of green technologies and high-performance treatment solutions. The rest of the world, including Latin America, the Middle East, and Africa, accounts for around 10% of the market share, experiencing gradual growth driven by the increasing adoption of industrial boilers and expansion in the energy and manufacturing sectors, with substantial potential for growth as industries modernize.

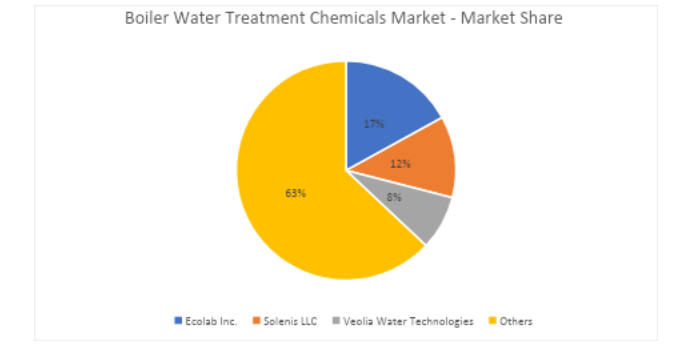

The boiler water treatment chemicals market is highly competitive, with several leading players dominating the landscape. Ecolab Inc., Solenis LLC, and Veolia Water Technologies are among the key organizations shaping the market. Ecolab held the largest market share of approximately 17% in 2023, followed by Solenis LLC with a 12% share, and Veolia Water Technologies at 8%. These companies are heavily investing in research and development to enhance their product offerings and maintain a competitive edge, focusing on innovations that improve energy efficiency, sustainability, and water treatment performance. Strategic mergers, acquisitions, and partnerships are also prevalent in the market, as these companies aim to expand their portfolios and strengthen their presence globally. As the demand for sustainable and efficient water treatment solutions grows, new entrants are expected to increase competition in the market, particularly in emerging economies in the Asia-Pacific region, which are experiencing rapid industrialization and infrastructure development.

Boiler water treatment chemicals play a crucial role across various industries due to their ability to enhance boiler efficiency, prevent scaling and corrosion, and ensure the longevity of boiler systems. Compared to traditional methods, such as mechanical cleaning or untreated water usage, these chemicals offer a more consistent and effective approach to maintaining water quality, making them indispensable in sectors like power generation, manufacturing, and food processing. As of 2024, boiler water treatment chemicals account for approximately 40% of the overall industrial water treatment chemicals market, with cooling water treatment chemicals and other specialty chemicals capturing 35% and 25% of the market share, respectively. The market share of boiler water treatment chemicals is projected to increase to 42% by 2025, driven by the rising demand for energy-efficient and sustainable solutions across industries. Their ability to optimize heat transfer, reduce energy losses, and comply with stringent environmental regulations makes them a preferred choice, particularly in regions experiencing rapid industrialization and infrastructure growth. This trend underscores the increasing reliance on boiler water treatment chemicals in industries prioritizing operational efficiency and environmental sustainability.

Environmental Impact Challenges in the Boiler Water Treatment Chemicals Market

While the boiler water treatment chemicals market is pivotal in ensuring the efficiency and longevity of boiler systems, it faces notable challenges related to environmental impact. The usage of certain chemicals, such as phosphates, amines, and oxygen scavengers, raises environmental concerns due to their potential to contribute to water pollution and ecosystem disruption when improperly disposed of. For instance, phosphates, widely used to prevent scaling, can lead to eutrophication in water bodies, causing excessive algae growth and subsequent depletion of oxygen levels, which threatens aquatic life. This environmental risk has prompted stricter regulatory measures, such as the Clean Water Act in the United States, necessitating industries to adopt alternative solutions or advanced disposal techniques.

Moreover, the disposal of chemical-laden boiler blowdown water poses a significant challenge. Boiler blowdown, which involves releasing water to control impurities and chemical concentration, often contains dissolved and suspended solids, heavy metals, and residual treatment chemicals. Improper management of blowdown can result in soil and water contamination. For example, studies have indicated that untreated blowdown water can elevate levels of lead and other heavy metals in nearby environments, exceeding permissible limits. To address these challenges, industries must invest in advanced wastewater treatment systems, which can increase operational costs and complexity.

Additionally, the production of boiler water treatment chemicals itself contributes to the carbon footprint, as it involves energy-intensive manufacturing processes and the use of non-renewable raw materials. The transportation and storage of these chemicals further exacerbate greenhouse gas emissions. These environmental concerns have driven industries to explore more sustainable options, such as biodegradable and eco-friendly treatment chemicals, though these alternatives often come with trade-offs in cost and performance. As global regulatory frameworks become increasingly stringent, the environmental impact of boiler water treatment chemicals remains a critical constraint, urging industries to innovate and adopt greener practices.

Expected Future Developments in the Boiler Water Treatment Chemicals Market

The boiler water treatment chemicals market is poised for significant advancements as industries increasingly prioritize efficiency, sustainability, and operational reliability. The technological roadmap for the market showcases a progression from traditional water treatment solutions to sophisticated chemical formulations tailored for modern industrial requirements. These advancements are driven by a growing need to address energy efficiency, reduce operational costs, and comply with stringent environmental regulations. For instance, in January 2024, BV Water introduced advanced boiler treatment chemicals. These innovative formulations are designed to enhance boiler efficiency, minimize scaling, and extend the lifespan of equipment while incorporating eco-friendly compounds to support sustainable industrial practices.

The evolution of the boiler water treatment chemicals market reflects continuous innovation in material science and formulation techniques. Early-stage solutions focused on mitigating scaling and corrosion to maintain boiler performance. However, as industries demanded greater efficiency and environmental responsibility, manufacturers began incorporating advanced inhibitors and dispersants that optimize heat transfer while minimizing chemical usage. Recent formulations, such as those introduced by BV Water, integrate biodegradable and non-toxic components, making them more aligned with global sustainability goals. These advancements have extended the applicability of boiler water treatment chemicals across industries, ranging from power generation to food processing and manufacturing.

Another key trend shaping the market is the integration of digital technologies and real-time monitoring systems. These systems enable precise control over chemical dosages and water quality, significantly improving the efficiency of treatment programs while reducing waste. Such technologies have become critical for industries adopting smart manufacturing and energy-efficient processes. Looking forward, innovations in nanotechnology and bio-based formulations are expected to further transform the market, enabling the development of highly targeted and effective solutions that meet the diverse needs of global industries. The boiler water treatment chemicals market is on a promising trajectory, with a strong focus on innovation, efficiency, and sustainability shaping its future.

Conclusion

The boiler water treatment chemicals market is evolving rapidly, driven by the interplay of technological advancements, sustainability goals, and the industrial need for optimized operations. This transformation is not only reshaping how industries manage boiler efficiency and water quality but also addressing pressing concerns such as energy conservation, environmental compliance, and operational cost-effectiveness. In an era where energy efficiency is paramount, the role of water treatment chemicals in enhancing heat transfer, reducing scaling, and preventing corrosion has become indispensable. As industries strive to minimize energy losses and maintain operational continuity, the adoption of advanced chemical solutions is gaining momentum.

Sustainability is another critical driver shaping the future of this market. With global regulations becoming stricter and public awareness about environmental preservation rising, industries are turning to eco-friendly and biodegradable water treatment chemicals. This shift is encouraging manufacturers to focus on green chemistry innovations that balance high performance with minimal environmental impact. Furthermore, the integration of digital technologies, such as real-time monitoring systems and AI-driven analytics, is redefining how water treatment programs are implemented. These technologies enhance precision, reduce wastage, and optimize chemical dosing, making boiler operations more efficient and environmentally responsible.

Author's Detail:

Nisha Deore /

LinkedIn

Nisha Deore is a highly skilled Research Analyst with over three years of experience specializing in food & beverage sectors. Her expertise encompasses secondary research, data mining, competitive analysis, and the development of detailed collateral and PR materials. Known for her meticulous approach, Nisha designs robust research methodologies and delivers actionable insights that support her organization’s commercial and financial objectives.

In her current role, Nisha manages research for food & beverage categories, leading initiatives to uncover market opportunities and enhance competitive positioning. Her strong analytical skills and ability to provide clear, impactful findings have been crucial to her team’s success. With a deep passion for both sectors and a commitment to continuous professional development, Nisha remains an invaluable asset in the dynamic landscape of market research.